186-6108-0091

Ultrasonic metal welding machine is a new type of mechanical equipment. It uses the basic principle of ultrasonic high-frequency vibration friction to convert the energy generated by ultrasonic vibration into frictional kinetic energy. Ultrasonic welding machine manufacturers transfer to the metal surface for welding through electric welding. Under the conditions of heat generated by friction and pressure applied thereto, the molecular structure of the metal part is sufficiently excited to produce an intermediate weld of the molecular structure layer.

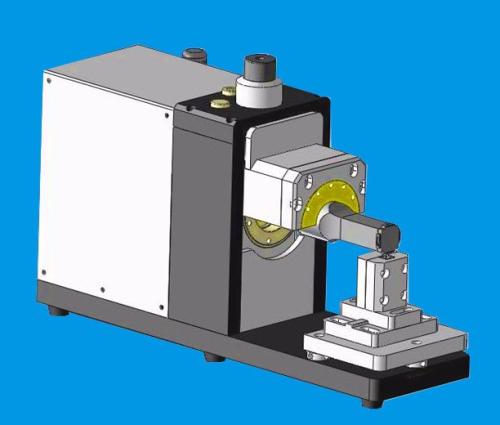

Ultrasonic metal welding machine

Dissolution method: Under proper working pressure, the ultrasonic mold with ultrasonic ultra-high frequency vibration makes the welding surfaces of two pieces of plastic melt instantaneously and connect tightly. The compressive strength of electric welding can be matched by itself. Choosing suitable products and effective interface design can achieve airtightness and airtightness, avoid the trouble of choosing auxiliary products, and clean and complete the dissolution.

Riveting welding method: pressing the ultrasonic mold with ultra-high frequency vibration on the protruding treetop of the plastic product, causing it to instantaneously burn and melt into a bolt shape, riveting the raw materials and mechanical equipment of different materials together.

Implantation: Metal components (such as nuts, extruder screws, etc.) are instantly squeezed into the wall of the embedded plastic hole through the conduction of the ultrasonic mold and moderate working pressure, and are fixed in a certain deep layer. After proceeding, regardless of the tension and torque, it can be matched with the compressive strength of traditional in-mold molding, thereby avoiding the defects of injection mold disassembly damage and slow injection.

Forming: This method is similar to the riveting method, in which a concave ultrasonic mold is pressed on the outside of the plastic product. After the ultrasonic mold emits ultrasonic ultra-high frequency vibration, the plastic is melted and formed, and then wrapped and fixed with metal materials, the appearance is bright and beautiful. This method is mostly used for the fixed molding of electronic devices and speakers, as well as fixed glasses for skin care products.

Welding: A. Welding the two plastic mesh points does not need to design the welding wire in advance to achieve the purpose of welding. B. For large and medium-sized product workpieces, and for product workpieces that are not easy to design weld seams, spot welding should be used to achieve the actual effect of dissolving welding, and more welding can be performed.

Laser cutting and sealing: Laser cutting of chemical fiber fabrics using the principle of ultrasonic instantaneous vibration. Its advantages are smooth winding, no cracks, and no metal wire drawing.

Contact: Manager Zhang

Tel: 18661080091

Contact: Manager Wang

Tel: 15052254070

Contact: Manager She

Tel:18651028660

Telephone: 0510-85855767 / 0510-83760992

Email: mxter168@163.com

Address: Building 1, No. 6, Chunhui Road, Huishan Economic Development Zone, Wuxi City

(Scan on WeChat)